Powder Coating Guns are the unsung heroes of the powder coating world, enabling professionals and enthusiasts alike to achieve stunning, durable finishes. As one seasoned metalworker put it, "A good

Powder Coating Gun is like an extension of your hand, allowing you to bring your creative visions to life with ease." Another user praised, "Once I switched to a quality

Powder Coating Gun, the difference in my projects' quality was night and day."

A

Powder Coating Gun is a sophisticated device. It typically features a handle for comfortable grip, connected to a powder delivery system. The powder delivery system consists of a hopper to store the powder and a mechanism to control the flow rate. In electrostatic powder coating guns, there is an electrostatic charging assembly. This assembly imparts an electric charge to the powder particles, making them adhere better to the grounded workpiece. The nozzle of the gun is designed to atomize the powder, ensuring an even spray pattern. Some advanced models also have adjustable air caps to modify the spray shape.

Powder Coating Guns find extensive use in various industries. In the automotive sector, they are employed to coat car bodies, engine components, and wheels, providing a smooth and long-lasting finish. Furniture manufacturers use these guns to coat metal frames, enhancing both the aesthetic appeal and durability. In the electronics industry, powder coating guns are utilized to coat metal enclosures of devices, offering protection against environmental factors. DIY enthusiasts also rely on these guns for customizing small metal items like home decor pieces and hobby projects.

The cost of a

Powder Coating Gun varies based on its features and quality. Basic manual powder coating guns, suitable for occasional DIY use, can range from $100 to $300. These guns usually have simple powder flow control. Mid-range guns, which often come with electrostatic charging capabilities and better build quality, are priced between $300 and $800. High-end professional-grade powder coating guns, equipped with advanced features like precise flow control and multiple spray patterns, can cost over $800.

Before using the

Powder Coating Gun, fill the hopper with the appropriate powder and ensure all connections are secure. Adjust the powder flow rate and, if applicable, the electrostatic charge settings according to the workpiece and powder type. Hold the gun approximately 15-20 cm away from the workpiece and keep it perpendicular during spraying. Move the gun steadily in a back-and-forth motion to achieve an even coat. After use, clean the gun thoroughly to prevent powder buildup.

When choosing a

Powder Coating Gun, consider your usage frequency. For frequent and professional use, invest in a high-quality, advanced model. If you're a beginner or only use it occasionally, a basic model may suffice. Evaluate the type of work you'll be doing. Complex shapes may require a gun with adjustable spray patterns. Also, check the brand's reputation for reliability and after-sales support.

Always wear a dust mask, safety goggles, and gloves when using a

Powder Coating Gun to protect against powder inhalation and potential splashes. Ensure the work area is well-ventilated to avoid the accumulation of powder particles. Keep the gun away from flammable materials, as powder can be combustible.

The design of a

Powder Coating Gun, especially the electrostatic charging feature in some models, significantly improves powder adhesion, resulting in a higher quality finish. The adjustable powder flow and spray patterns offer flexibility for different projects, enhancing efficiency. The ergonomic handle design reduces operator fatigue during long-term use.

Q: What if the powder coating is uneven when using the

Powder Coating Gun?

A: Check the powder flow rate and adjust it if needed. Also, ensure the gun is at a consistent distance and angle from the workpiece. If it's an electrostatic gun, verify the electrostatic charge settings.

Q: Can I use different powder types with the same

Powder Coating Gun?

A: Yes, but it's essential to clean the gun thoroughly between different powder types to avoid contamination, which could affect the coating quality.

Q: How often should I clean my Powder Coating Gun?

A: Clean the gun after each use to prevent powder buildup, which can impact its performance. For a more in-depth cleaning, disassemble the gun periodically and clean each component.

Q: What if the powder doesn't flow properly from the Powder Coating Gun?

A: Check the powder hopper for blockages and make sure the powder flow control mechanism is working correctly. Also, ensure the powder is not too moist or compacted.

Q: Can I upgrade the features of my Powder Coating Gun?

A: In some cases, it might be possible to upgrade certain features, such as adding an electrostatic charging kit or replacing the nozzle. However, this depends on the gun's design and compatibility. It's best to consult the manufacturer or a professional for advice.

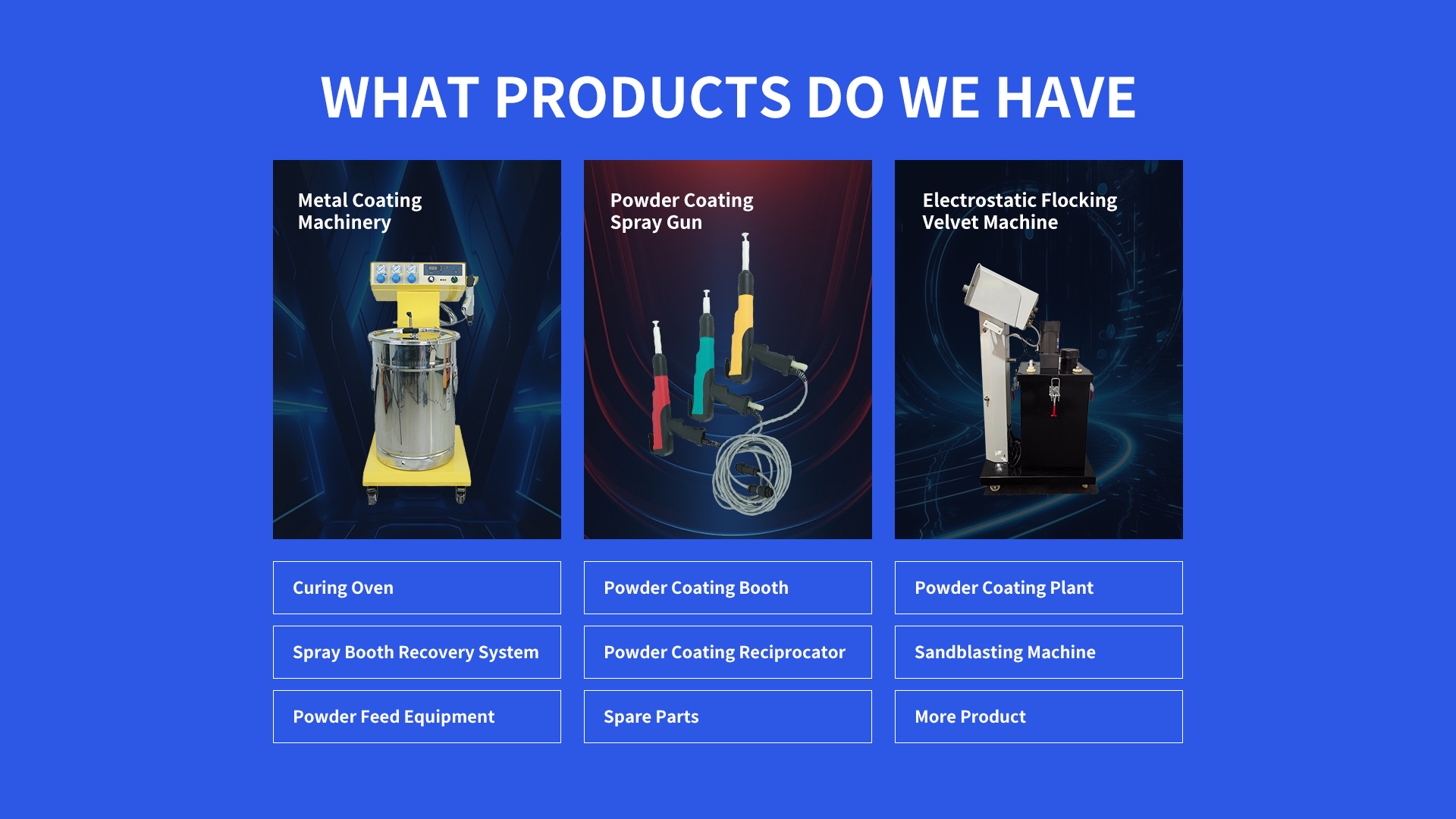

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com